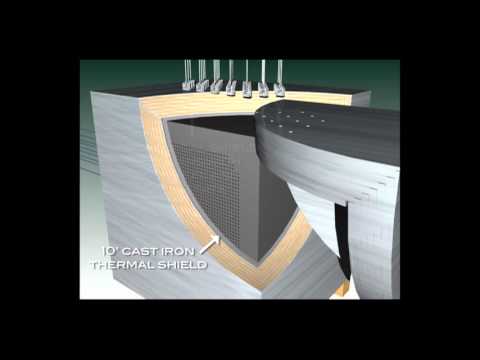

Reactor assembly, the nitrogen in normal air would absorb neutrons, so the atmosphere inside the reactor is helium. The helium distribution piping is buried in the massive 23-foot thick concrete base foundation for the reactor. At the top ends of the helium piping system, the ductwork that will direct the helium into the graphite stack can be seen on top of the base concrete. A quarter-inch steel plate is laid, and it will connect to the other steel lining of the insides of the shields to form an airtight barrier for the helium. The next material laid down is a 10-inch thermal shield of cast iron, which will also be added between the graphite stack and the top and side biological shields. The front and top biological shields, with penetrations for the process tubes, were prefabricated in Northwest shipyards as 4-foot cubes weighing 10 tons. The dimensional tolerances for these B blocks were incredibly tight to allow them to be stacked 35 feet high and still be able to precisely align the front face top tube holes with the corresponding holes in the graphite and then the holes in the rear block. While the shield walls are being completed, the enormous piping system to deliver the required 30,000 gallons per minute of cooling water was put in place. The water from the pump house next to the reactor building arrives at the reactor front face through 2 20-inch diameter risers on each side. Four-inch diameter cross header pipes connect to the risers and run under each of the 46 rows of process tubes inside the shield. The 75,000 graphite blocks are now laid down in alternate layers, one layer side to side, and the next layer front to back. The board two blocks are laid down to match the holes...

Award-winning PDF software

Video instructions and help with filling out and completing Are Form 8655 Authorizes